Hydraulic Baler Machine Hay Baling Equipment

| Model | 9YK-70 |

| Power | 15kw motor or 28HP diesel engine |

| Displacement of oil cylinder | 63-80L/min |

| The normal pressure of oil cylinder | 16Mpa |

| Bale size | 700*400*300mm |

| Bale Density | 300-400kg/h |

| Bundling efficiency | 1-2t/h |

| Weight | 1500kg |

| Dimension | 3400*2800*2700mm |

| Speed of Bundling Piston | 4-8m/min |

You can now ask our project managers for technical details

The silage hydraulic baler machine is a high-efficiency equipment designed for baling and storage of forage, straw, corn stalks and other crop stalks.

Through the hydraulic extrusion system, it can compress loose straw and forage into tight square bales (700×400×300mm standard blocks) with a density ≥800kg/m³.

And it adopts PE+PP double-layer packaging, which enhances the activity of forage lactic acid bacteria by 300% and the nutrient preservation rate>85%. , the freshness preservation period is up to 2-3 years.

According to the production demand, the equipment is divided into two models: double-cylinder hydraulic baler and three-cylinder hydraulic baler:

- Double-cylinder hydraulic baler: support motor or diesel engine drive, applicability, convenient and flexible.

- Three-cylinder hydraulic baler: only support motor drive, higher efficiency, greater density of finished products, higher capacity per hour.

At the same time, it can be used with guillotine crusher to cut the grass first and then enter the baling process to improve the baling effect and silage quality.

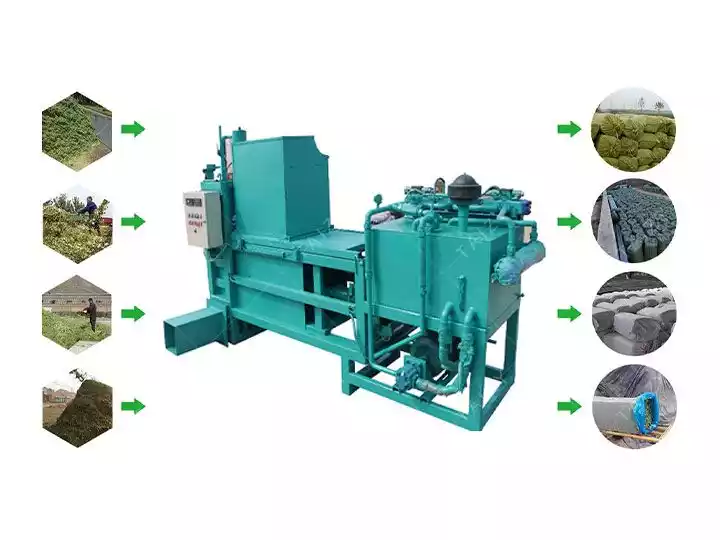

Using scopes of silage hydraulic baler

Raw materials: The hydraulic baler machine can process straw, hay, sorghum, corn silage, corn straw, wheat straw, peanut seedlings, cotton straw, alfalfa grass, mycorrhiza, etc. We can use these forages to feed cattle, sheep, horses, pigs, rabbits, and other livestock.

Users: The hydraulic baler machine is indispensable equipment for animal husbandry, paper making, cattle and sheep breeding, forage distribution, and straw power generation.

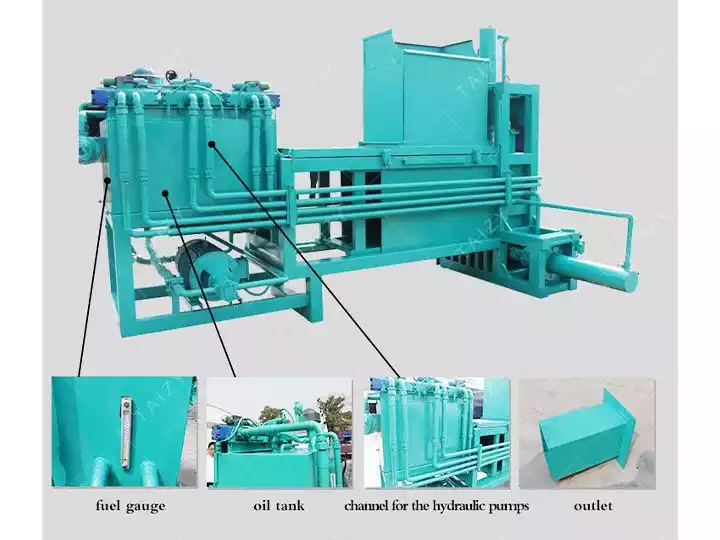

Structure of hydraulic press baler machine

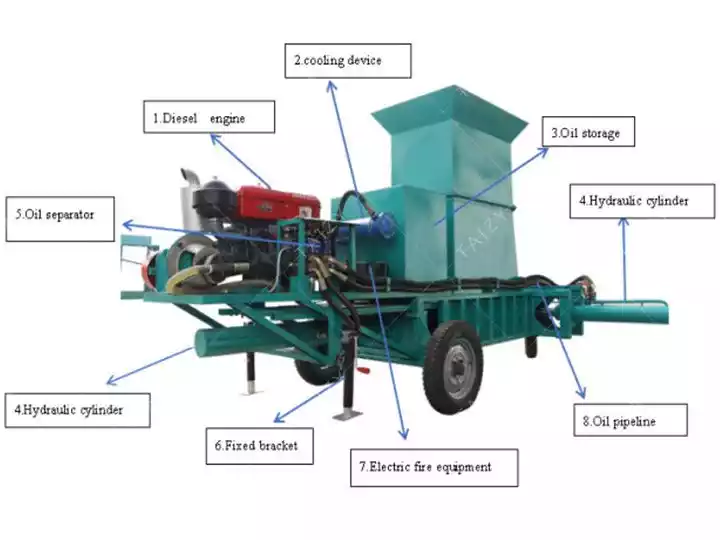

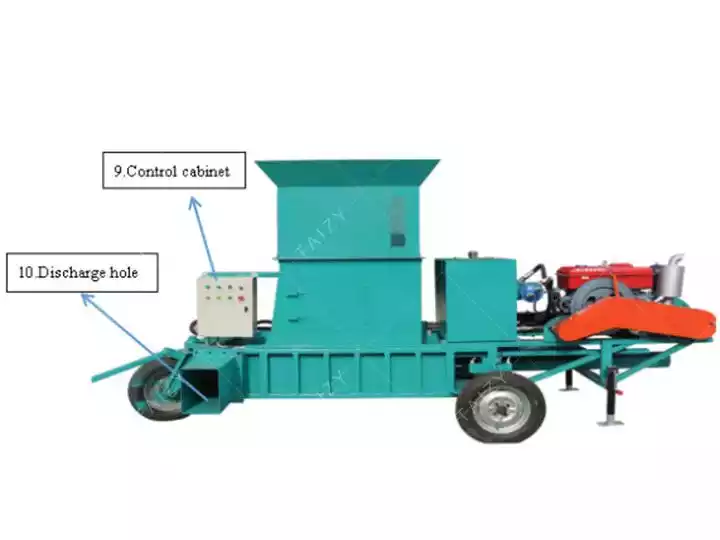

Double-cylinder hay and straw baler structure

This model OF hydraulic baler machine mainly includes a fixed bracket, power, cooling device, oil reservoir, hydraulic cylinder, electric fire fighting equipment, oil pipeline, oil separator, etc.

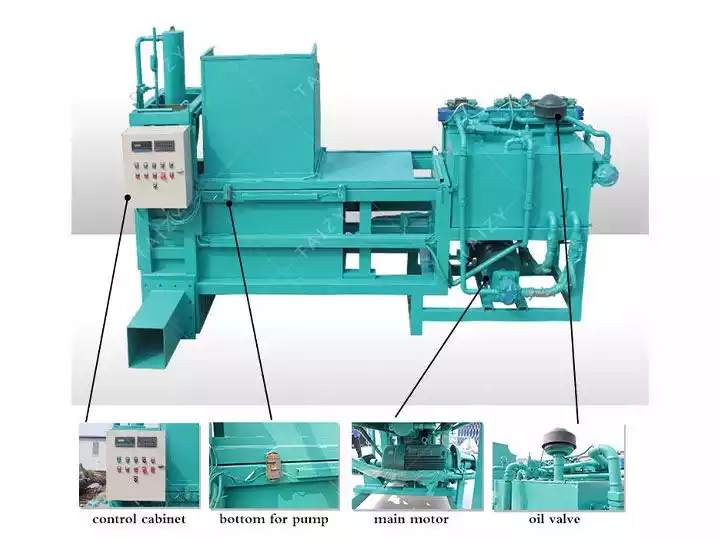

3-cylinder hydraulic baler structure

Hydraulic baler machine’s parameters

Double cylinder baler

| Model | 9YK-70 |

| Power | 15kw motor or 28HP diesel engine |

| Displacement of oil cylinder | 63-80L/min |

| The normal pressure of oil cylinder | 16Mpa |

| Bale size | 700*400*300mm |

| Bale Density | 300-400kg/h |

| Bundling efficiency | 1-2t/h |

| Weight | 1500kg |

| Dimension | 3400*2800*2700mm |

| Speed of Bundling Piston | 4-8m/min |

Three-cylinder silage baler machine

| Item | 9YK-130 |

| Power | 22kw |

| Displacement of Oil Cylinder | 80L/min |

| Normal Pressure of Oil Cylinder | 18Mpa |

| Bale Size | 700*400*300mm |

| Bundling Efficiency | 6-8t/h |

| Bale Density | 800-1100kg/m3 |

| Weight | 2600kg/h |

| Dimension | 4300*2800*2000mm |

| Speed of Bundling Piston | 4-8m/min |

How does the hydraulic baler work?

Both of them put the forage into the machine first. Turn on the hydraulic baler machine, when the main cylinder is pushed horizontally and compacted, and the side cylinders are compacted longitudinally. Finally, the pushing head pushes the bale into the bag. Finish all the baling process.

Prepare the grass, straw, or other raw materials into the entrance of the hydraulic baler machine by manual drop or conveyor belt.

The hay cutting machine or straw kneading machine crushes the added raw materials and grinds them for processing and making.

The straw bag is placed at the exit to package the finished material after processing.

Automatic control cabinet, one key to start processing and packaging, simple and convenient.

The volume and size of the processed material are consistent, in line with the packaging standards, and convenient for transportation and storage.

Advantages of silage hydraulic press baler

- Large-size horizontal sleeve type baling, regular bale shape, good sealing, easy to store and transport.

- Convenient installation, simple maintenance, small footprint, saving site costs.

- Adopting high and low pressure combined hydraulic system, fast and efficient operation, saving power, labor and time.

- Key components are sealed original parts, long cylinder life and low failure rate.

- It can bale silage straw, dry corn stalks, all kinds of chopped straw, waste plastic film, etc., and realize automatic bagging and packaging.

- It adopts conveyor belt feeding and double-cylinder balanced compression, and the special hydraulic system ensures stable power output.

- There is no need to dig silage ponds, saving a lot of manpower (the whole set of equipment only needs 2-3 people to operate), space and packaging costs, and the silage preservation period can reach 3 years.

- After packing and sealing, the silage is naturally fermented, rich in probiotics, lactic acid bacteria and proteins, which is easy to be absorbed by livestock and promotes the growth rate to be increased by more than 2%.

Other machines that can be matched

As the hydraulic baler machine handles more forage, the feed opening is higher. Therefore we recommend using a forage crushing machine to first crush the straw. Then connect the conveyor belt to send the crushed material into the hydraulic baler. You can also use the feed mixer to mix the different forages evenly and then connect the conveyor belt to the machine.

Successful cases

Last week a customer from Kenya purchased a hydraulic baler machine from us. The customer has a livestock farm and wants to keep fresh forage to feed throughout the year. The customer searched online for a machine that could store forage for a long time.

And he entered our website. After browsing, the customer was interested in our hydraulic baler machine and contacted us via WhatsApp. So, we talked to him about all aspects of the machine. And then the customer decided to buy a two-cylinder hydraulic baler.

Whether you have any questions or need more detailed information, we welcome your inquiries at any time. We sincerely invite you to visit our factory and look forward to cooperating with you.