Silage Chaff Cutter Animal Feed Grass Cutting Machine

| Model | 9Z-1.2 |

| Supporting power | 3kw single-phase motor |

| Motor speed | 2800 rpm/minute |

| Machine weight | 80KG |

| Dimensions | 880*1010*1750mm |

| Production efficiency | 1200KG/H |

| Number of blades | 6 |

| Feeding method | Manual feeding |

| Discharging effect | 7-35mm |

| Structure type | disc |

You can now ask our project managers for technical details

Our multifunctional silage chaff cutter is designed for modern farms, which can meet the demand for fine feeding of different livestock such as cows, sheep, pigs, and so on in different sizes of farms.

From family farms to large-scale breeding bases, we offer a full range of models, equipped with electric, gasoline and diesel power systems, with a flexible choice of daily handling capacity from a few tons to tens of tons.

The silage chaff cutter can be matched with a silage baling and wrapping machine, a conveyor belt, and other equipment to form an automatic production line. This can realize one-stop operation from raw material processing to finished product packaging, helping you to improve feed processing and reduce labor costs.

Application range of animal feed chaff cutter machine

Our silage chaff cutters can efficiently process all kinds of crop stalks and forage raw materials, including green (dry) corn stalks, rice-wheat straw, soybean seedlings, elephant grass, and so on.

The processed high-quality feed is especially suitable for cattle, sheep, deer, horses and other livestock breeding, which can significantly improve the palatability and nutritional value of feed.

In addition to livestock breeding, the equipment is also widely used in:

- Biomass energy: providing standardized straw raw materials for power plants.

- Paper industry: pre-treatment of various types of herbal fiber raw materials.

- Ethanol refining: high-quality plant raw materials for the preparation of biofuel.

- Chinese herbal medicine processing: precise cutting of medicinal plant material.

Type 1: 9Z-0.4 grass cutting machine

Designed for family farms and small farms, the 9Z-0.4 silage chaff cutter machine is compact but powerful!

Adopting high-precision alloy blade set as the core cutting system, through the adjustable blade design, you can freely control the cutting length of grass (1-5cm optional), perfectly adapted to the feeding needs of different livestock.

Parameters of grass cutting machine

| Model | 9Z-0.4 |

| Supporting power | 3kw electric motor |

| Motor speed | 2800 rpm |

| Machine weight | 60KG(not include motor) |

| Dimensions | 1050*490*790mm |

| Production efficiency | 400-1000KG/H |

| Number of blades | 4/6 |

| Feeding method | automatic feeding |

| Discharging effect | 10-35mm |

| Structure type | Drum type |

Working performance of the silage cutter

Type 2: 9Z-0.4 square mouth grass chopper machine

The top of this grass chopper machine is specially equipped with a multifunctional square feeding port, which allows you to easily add a variety of nutritious auxiliary materials such as sugar cane head, sweet potato, soybean, etc. while chopping grass, realizing the golden ratio of feed nutrition.

Detailed information on grass cutter

| Model | 9Z-0.4 chaff cutter with square mouth |

| Supporting power | 3kw electric motor |

| Motor speed | 2800 rpm/minute |

| Machine weight | 60KG |

| Dimensions | 1130*500*1190mm |

| Production efficiency | 400-1000KG/H |

| Number of blades | 4/6 |

| Feeding method | automatic/manual feeding |

| Discharging effect | 10-35mm |

| Multi-functional type | Cutting grass and vegetable |

Structure of the grass chaff cutter

The structure of Type I silage chaff cutter and Type II is similar. They both contain a cutting inlet, a guillotine chamber, a gearbox, moving casters, and a pure copper motor. The Type II silage chaff cutter has an additional square feed opening above the guillotine chamber. Below is the structure diagram of the Type I 9Z-0.4 chaff cutting machine.

What are the characteristics of a grass shredder?

- Rugged and durable design: full cast iron support and manganese steel body ensure the stability and wear resistance of the equipment, prolonging the service life.

- High-efficiency cutting system: three sets of movable knife + fixed knife beveled design, tangential feeding structure, reduce resistance by 30%, improve cutting uniformity.

- Intelligent silent energy saving: optimized structure reduces noise, gear drive reduces energy consumption by 20%, suitable for long time operation.

- Flexible and versatile high efficiency: double-roller feeding adjustable knife spacing (1-10cm), handling 0.5-1 tons per hour, efficiency 20 times higher than manual.

Type 3: Large straw chaff cutter

- Our range of high-power silage chaff cutters includes 8 models from 9Z-1.2 to 9Z-10A, each of which is designed with a long-necked outlet to ensure a longer and smoother delivery of the hay.

- The 9Z-2.5A and 9Z-10A models are especially equipped with an automatic feeding system, which realizes full automation and greatly improves production efficiency.

- In terms of power selection, the whole series supports three configurations of electric motor, diesel engine and gasoline engine, and the models above 1.8 tons are recommended to be driven by more powerful electric motor or diesel engine to ensure stable operation for a long time.

- The unique jet discharging system can powerfully spray the treated grass 8-15 meters, the discharging height and angle can be freely adjusted, easy to dock the transportation vehicle or storage silo.

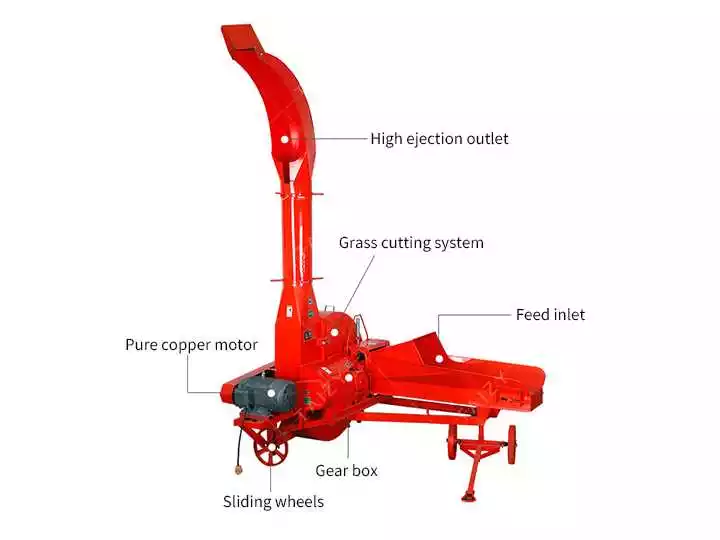

Structure of large straw chaff cutting machine

The structure of the large silage chaff cutter is similar: both of them contain a feed inlet, gearbox, cutting device, high spout, motor/diesel engine, moving wheels, frame, etc.

Parameters of 9Z-1.2 straw cutting machine

| Model | 9Z-1.2 |

| Supporting power | 3kw single-phase motor |

| Motor speed | 2800 rpm/minute |

| Machine weight | 80KG |

| Dimensions | 880*1010*1750mm |

| Production efficiency | 1200KG/H |

| Number of blades | 6 |

| Feeding method | Manual feeding |

| Discharging effect | 7-35mm |

| Structure type | disc |

Advantages of the large straw chopper

- Steel structure frame, small volume, lightweight, easy to move.

- Design an insurance device, to eliminate knife gnawing accidents, the machine is safe and reliable.

- The grass roller drive shaft uses universal coupling, compact structure, flexible operation, and easy disassembly, and assembly.

- The supporting power is various choices, electric motor, diesel engine, the tractor can be matched, especially for the lack of electricity in the region is more suitable.

- The machine blade is made of high-quality steel, refined by special technology, and wear-resistant. The use of high-strength bolts, the use of safe and reliable.

- Silage chaff cutter shell is made of a thickened steel plate continuously welded, the whole mold forming, beautiful, and durable.

Working principle of large straw cutter

Whether it is a large or small silage chaff cutter, the working principle is the same. The motor, diesel engine, and gasoline engine transmit the power from the belt to the main shaft. The gear at the other end of the main shaft transmits the speed-regulated power.

When the material enters between the upper and lower press rollers from the inlet. Then, the high-speed rotating knives quickly carry out the grass-cutting operation. Finally, the cut grass is thrown out of the machine through the outlet.

It can be used with baling film equipment later, please click for details: Automatic Corn Silage Baler Machine For Feed Preservation.

Successful case

A customer from the Philippines purchased a 9Z-1.2 silage chaff cutter from us. The customer has raised some cattle. Some time ago he decided to expand the scale of his breeding. Therefore, he also wanted to purchase a larger model of the guillotine to process forage.

If you have silage processing needs, please feel free to contact us for more equipment details, video demonstration and customized service!