Hay Cutter And Baler Silage Cutting Baling Machine

| Model | STF 70*100 |

| Working capacity | 0.82-1.3 acre |

| Size | 2300*2200*1450mm |

| Model | 9YFQ-2.2 |

| Picker width | 2240mm |

| Picker structure type | Spring tooth |

| Knotter type | D |

| Number of knotters | 2 |

| Reciprocation times of the bundled piston | 100/min |

| Dimensions(mm) | 4150×2850×1800 |

| Supporting power | ≥36.7kw |

You can now ask our project managers for technical details

The hay cutter and baler can crush and bale straw directly in the field. It meets the needs of people who want to bale straw or forage directly from the field. The machine saves time, labor, and transportation costs for collecting, transporting, and shredding straws. It can handle standing or fallen stalks, such as corn stalks, wheat stalks, cotton stalks, etc. And can accomplish 0.82-1.3 acre of farm straw recycling at one time.

What is the hay cutter and baler?

The hay cutter and baler can work in both pre-harvest and post-harvest fields. The machine crushes picks up and bales the straw as it appears in the work area. Therefore, it has more crushing functions than the straw picking baler. The baled straw can be dense and breathable for easy transportation and storage.

We produce two types of machines, square bale, and round bale straw crushing and picking balers. In addition to both using the tractor as power, they are different in structure and finished products. Here is a brief introduction to the two machines.

Using scopes of the silage cutting baling machine

We have two types of silage cutting baling machines. Both machines can handle standing or fallen corn, rice, wheat, wheat straw, alfalfa straw, sheep straw, reeds, cotton straw, etc. Because of the shredding function, they can work in the field before and after harvesting. And it has a good harvesting effect.

Type I: Round straw crushing and picking baler

This type of machine bales the finished product in a round shape. It can use rope and a net to bale the bales, and the size of the bales is 70*100mm, besides the harvesting width is 1.8m or 1.65m. The corresponding tractor sizes are greater than 75 hp and 60 hp.

How do the hay cutter and baler machines work?

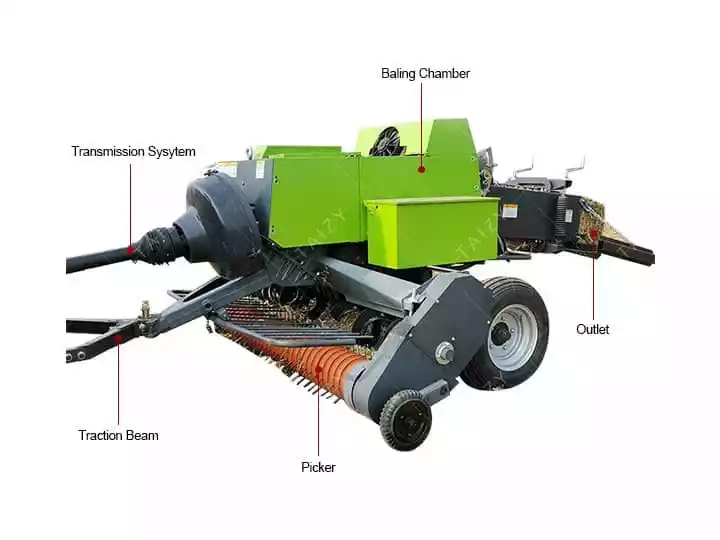

Structure of the hay cutter and baler

The hay cutter and baler mainly contain a straw chopping mechanism, transmission mechanism, picking mechanism, raking mechanism, piston stamping mechanism, bale pressing mechanism, and other parts.

Parameters of the small hay round baler

| Model | STF 70*100 |

| Working capacity | 0.82-1.3 acre |

| Size | 2300*2200*1450mm |

How does the tractor baler work?

The working principle of the tractor baler is to first knead and crush the thick, strong, and hard corn stalks. And under the inertia of the machine, the material will be thrown into the churn.

Then the churn will push the material to the feeding port, the feeding fork will send the material to the compression chamber.

Next, the piston will compress the straw under the reciprocating action.

So, the back of the baler bin will automatically alarm when the capacity is full. And the automatic rope will wrap the bale. And finally, open the bin and place the ball into the bales.

Highlights of the compact tractor baler

- The hay cutter and baler have a wide range of uses. It can harvest rice straw, hay, wheat straw alfalfa, and other stems of cereal grasses.

- The tractor baler has a simple structure, a low failure rate, and reliable work. The machine is easy to operate and the formed bales are small in shape and easy to carry.

- Because it is a pendant, it is suitable for small and medium horsepower tractors, which are flexible and mobile.

- After the bale is formed, the tractor comes with a hydraulic mechanism to control the cylinder, and the rear frame will open, spitting out the bale.

Type II: Square hay baler

The square straw crushing and picking baler can only use the rope to bale the material. The machine has a crushing width of 2.2m and needs to be driven by a tractor of 75hp or more. The size of the bale is 1100*400*300mm and the machine does not need to put the ball in operation, it will discharge the bale automatically. The user only needs to move at a certain speed in the field.

Detailed specifications of the hay cutter and baler

| Model | Picker width | Picker structure type | Knotter type | Number of knotters | Reciprocation times of the bundled piston | Dimensions(mm) | Supporting power |

| 9YFQ-2.2 | 2240mm | Spring tooth | D | 2 | 100/min | 4150×2850×1800 | ≥36.7kw |

Structure of the straw crushing baler

The straw crushing baler mainly includes a frame, walking wheel, traction beam, transmission system, compression device, baling device, picking device, packing device, etc.

Working scene of square hay baler

Advantages of the square press crushing baling machine

- The front tractor frame can rotate 180 degrees freely and turn flexibly, which solves the problem of tractor power limitation.

- This machine is firmly welded and adopts an enlarged gearbox and enlarged bearings, which are resistant to wear and tear.

- The blade can meet the requirements of different customers on the degree of straw crushing.

- The feeding shaft adopts a spiral propulsion auger knife, and wave-shaped transmission, solving the problem of tangled straw, and blocking material, and will not appear broken shaft.

- The machine adopts solid seamless steel pipe, wear-resistant and durable.

What are the differences between the two hay cutter and balers?

- Shape of the finished products of the two machines is different, one is a round bale and the other is a square bale.

- The material used to bale the grass is different, the round straw crushing and picking baler can use the net and rope. The square one can only use the rope to bale the grass.

- Internal structure of the two machines is also different, and the shape of the final product is different in size.

Our factory produces and manufactures different types of straw recycling machines, you can choose according to the demand and actual situation, and accept customization. Please feel free to contact us for more information and machine quotation.