How to make “bread grass” by the silage wrapping machine?

Silage wrapping is a method of preserving green and juicy green fodder under anaerobic conditions by using the silage wrapping machine. Currently, many livestock uses the silage wrapping machine to produce nutrition feed. This is because it is an important green and juicy feed for ruminant livestock such as cows, beef cattle, dairy sheep, meat goats, deer, horses, donkeys, etc. Besides, we also have the hydraulic hay baler machine, which can press the straw into the square bale.

The process of producing “bread grass” through a silage wrapping machine

Preparation work

(1) Straw pre-treatment site: the site depends on the scale of production, requiring a cement floor.

(2) Bread grass storage site: can be a large plant, but also open air.

(3) Power supply, water source.

(4) Stretching film and baling with string.

(5) Handling tools.

(6) Safety education and technical training for workers before they start work.

Specific bundling and wrapping process

I. Kneading

Because the kneaded straw is easy to bale and silage, improves the efficiency of fermentation and decomposition of crude fiber. Therefore, we need to use the grass cutting machine to knead the straw before the silage wrapping machine. The chaff cutter destroys the hard stalk surface by flattening, slitting, squeezing, and kneading the straw. Therefore, the straw, which cannot be eaten directly by livestock, is processed into shredded forage with good palatability. And at the same time does not lose its nutrients, easy for livestock to digest and absorb.

2. Baling

The kneaded forage is quickly, evenly, and uniformly sent into the working bin of the baler for compression. When the weight of each sill reaches a certain weight, that is, when the signal wheel has been randomly rotated at a uniform speed, the feeding should be stopped. At this time, the silage wrapping machine starts to use rope or net for baling. Then when the bundling is finished and the rope is cut off, the bale is opened and discharged. At this point, the baling process is completed.

3. Wrapping

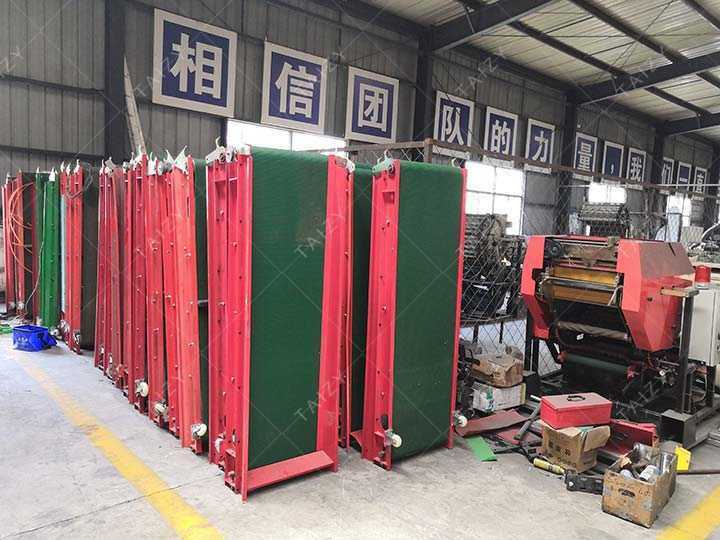

At this time, the bales are on top of the two parallel belts of the wrapping machine and the wrapping part starts to work. Therefore, the stretched plastic film of the bale starts to wrap itself and finish the wrapping work. When the number of wrapping layers is set (2 to 4 layers), the wrapping will stop by itself. Finally, the user can use the professionally equipped cart to palletize the wrapped forage neatly.

What are the advantages of Taizy forage film?

The silage wrapping machine solves the problem of creating an anaerobic environment for straw fermentation by using forage film wrapping technology.

- The forage film has a sticky surface, good bonding between layers, impermeable, and impervious to water.

- It is strong enough and soft enough to resist a low temperature, and will not freeze and crack in a cold environment.

- The pasture film is opaque to ensure low light transmission and avoid heat accumulation. The straw bales packed with it can be stored in the field for more than 2 years

- Generally, “bread grass” feed formed after one month of fermentation at 10℃ or above. 1 pound of bread grass is equivalent to 1.4 pounds of silage, 2 pounds of dry straw use value.