Stalk cutting recycling machine丨silage harvester machine

| Name | Chaff harvester |

| Engine | ≥60HP tractor |

| Dimension | 1.6*1.2*2.8m |

| Weight | 800kg |

| Harvesting width | 1.3m |

| Model | GH-400 |

| Recycling rate | ≥80% |

| Fling distance | 3-5m |

| Fling height | ≥2m |

| The length of crushed straw | Less than 80mm |

| Rotating blade | 32 |

| Cutter shaft speed | 2160r/min |

| Working speed | 2-4km/h |

| Capacity | 0.25-0.48h㎡/h |

You can now ask our project managers for technical details

The stalk cutting recycling machine is a multifunctional agricultural equipment integrating harvesting, crushing and recycling, which is suitable for the field processing of various crop straws and silage. It can help farmers to turn “waste materials” into resources for feed processing, biomass power generation and organic fertilizer production.

The equipment and tractor supporting operations, a machine multi-purpose, can realize the straw on-site crushing and direct recycling or return to the field. Its crushing granularity ≤ 5cm, and to achieve corn, wheat, rice and other crop straw more than 80% recovery rate.

This stalk cutting recycling machine is equipped with different harvesting widths such as 1.3m, 1.35m, 1.5m, 1.65m, 1.7m, 1.8m, and 2m, which are suitable for different sizes of farmland, and it can realize the ultra-efficient processing capacity of 0.25-0.48h㎡/h.

Using scope of silage harvester machine

Applicable objects (types of crops that can be treated)

- Corn stalks, cotton stalks, banana stalks, sorghum stalks, wheat straw, grain stalks and other crop stalks.

- All kinds of wet and dry mixed silage crops in the field.

- All kinds of orchard residual straw and biomass stalks after harvesting.

Scenarios and applications

- Farms and feed mills for silage or straw pellet feed processing.

- Charcoal factories, straw coal factories, etc. are used to produce straw charcoal, straw coal and biomass fuel.

- Used by edible mushroom growers to make cultivation substrate.

- It can be used as raw material for biomass power generation, realizing energy recycling.

How does silage harvester machine work?

When the tractor moves forward in the field, the machine is driven to synchronize the operation, and the front-end cutting table sends the straw harvested into the crushing device for shredding.

Subsequently, the crushed straw is collected into the recycling box through the conveying system, or returned to the field directly, realizing the integrated and efficient operation of harvesting, crushing and recycling.

Structure of stalk cutting recycling machine

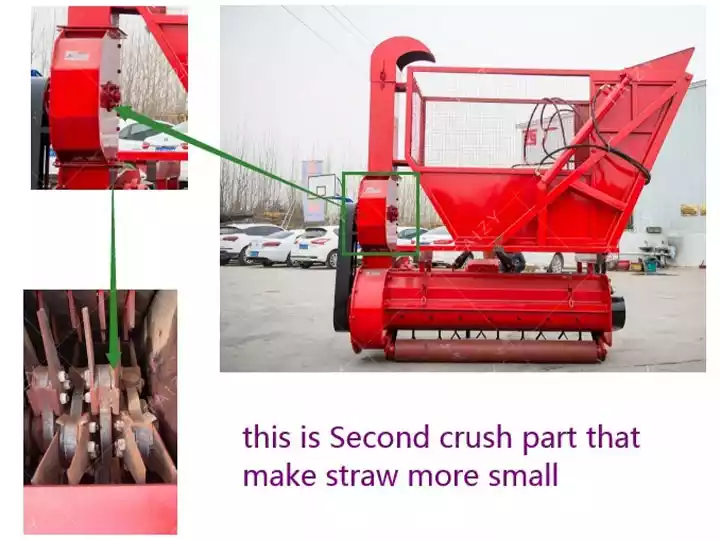

The structure of the stalk cutting recycling machine is simple and easy to operate. The machine mainly includes a crushing chamber, hydraulic automatic unloading device, 60HP tractor, crushed straw container, PTO driven, hydraulic device, etc.

Corn silage harvester parameters

| Name | Chaff harvester |

| Engine | ≥60HP tractor |

| Dimension | 1.6*1.2*2.8m |

| Weight | 800kg |

| Harvesting width | 1.3m |

| Model | GH-400 |

| Recycling rate | ≥80% |

| Fling distance | 3-5m |

| Fling height | ≥2m |

| The length of crushed straw | Less than 80mm |

| Rotating blade | 32 |

| Cutter shaft speed | 2160r/min |

| Working speed | 2-4km/h |

| Capacity | 0.25-0.48hm2/h |

Advantages of trailed forage harvester

- Multi-functional integration: integrating cutting, kneading, crushing and harvesting to meet different operational needs.

- High efficiency and low consumption: the operation process is simplified into one procedure, with high operation efficiency and remarkable energy-saving effect.

- Low comprehensive cost: low energy consumption, high output, lower overall cost and strong economy.

- Widely applicable: it can be adapted to a variety of dry and wet straw crops, suitable for a variety of land environment, and has strong applicability.

- Promote green agriculture: help the comprehensive utilization of biomass energy, is the ideal equipment for the development of environmentally friendly agriculture.

Successful cases

A customer from Malaysia bought a 1.3m stalk cutting recycling machine from us. He feeds cattle and sheep in his local area. To get sufficient feed, the customer needed a straw grinder to process the corn stalks.

We sent the pictures, parameters, and video of the machine to the customer. After consideration, the customer decided to buy one. After the customer received the stalk cutting recycling machine, he used it for a while. He said the machine performed very well and he was satisfied with it and looked forward to the next cooperation with us.

In addition to straw crushing and recycling machines, we also have other kinds of silage and other processing equipment, such as forage baling wrapping machines and hydraulic balers. You can browse our website to choose the right machine by yourself. Welcome to contact us anytime!

FAQ

What is the function of the stalk cutting recycling machine?

The function of straw crushing and recycling.

Can I buy only the crushing part?

Yes, you can crush the straw separately (the price is also cheaper). It is recommended that you use a hopper truck to follow the shredder.

Can you handle dry straws?

Yes, but green straw is the best for freshness and storage for animals.

How much horsepower does the machine need?

80 hp tractor, different harvesting width with different tractor horsepower sizes, to confirm the customer tractor horsepower size.

What is the height of the stubble after crushing?

8-15cm.

What is the fineness of the crushed straw?

It is 3-5cm.