Automatic Corn Silage Baler Machine For Feed Preservation

| Model | TS-55-52 |

| Power | 5.5+1.1kw, 3 phase |

| Bale size | Φ550*520mm |

| Diesel engine | 15 hp |

| Baling speed | 40-50 piece/h, 4-5t/h |

| Size | 2135*1350*1300mm |

| Machine weight | 850kg |

| Bale weight | 65-100kg/bale |

| Bale density | 450-500kg/m³ |

| Rope consumption | 2.5kg/t |

| Wrapping machine power | 1.1-3kw, 3 phase |

| Film wrapping speed | 13s for 2-layer film,19s for 3-layer film |

You can now ask our project managers for technical details

Model 55-52 corn silage baler machine realizes Φ550×520mm standard bale molding + full-automatic wrapping, and the production efficiency can reach 60-90 bales/hour.

The production efficiency can reach 60-90 bales/hour. With this machine, the density of bales can be increased by 40%, and with 2-6 layers of adjustable film wrapping technology, the silage open-air preservation cycle can be extended to 2-3 years.

The model adopts a dual-power adaptive system, equipped with a 5.5 kW electric motor or an 8 hp diesel engine, which adapts to continuous operation in an unstable power grid area.

It realizes full process automation from feeding, baling to wrapping, and only 1-2 operators are needed to complete 50 tons of silage production per day.

Using range of corn silage baler machine

The corn silage baler machine can handle corn stalks, alfalfa, sugar cane tail leaves, groundnut vines, reeds, bean seedlings, silage from sodas, etc.

These silages have high commercial value after micro-silage, which makes the waste of crops into treasure and improves the utilization rate of resources. We can then feed the baled silage to cattle, sheep, rabbits, deer, horses, pigs, camels, etc.

New PLC-type baling and wrapping machine

Below is a new PLC-type silage baling and wrapping machine. This machine now has a fully automatic film-cutting function, so there is no need to tear the film manually, which greatly improves working efficiency and operation convenience.

Upgraded and improved silage baler machine

Our facility features several innovative upgrades to our corn silage baler machines, allowing you to boost productivity while reducing downtime and maintenance needs. Here are the key upgrades we’ve implemented:

Improved mobility and durability

- Replace the small rubber tires with larger solid ones to enhance maneuverability and lower the chances of tire rupture.

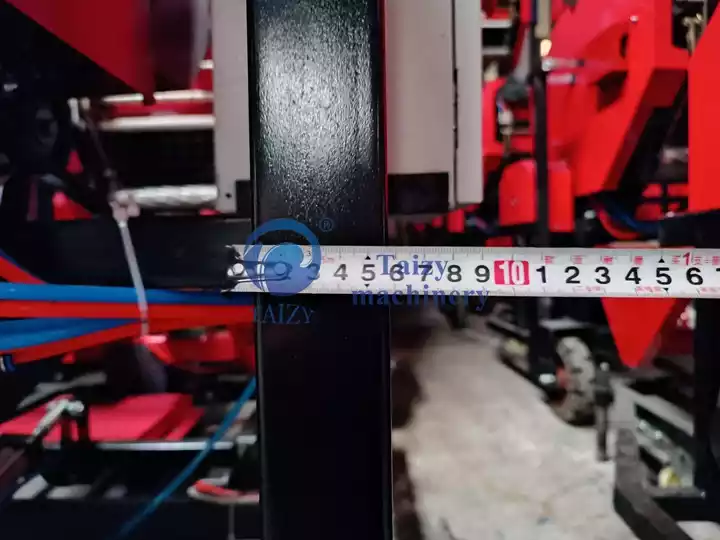

- Reinforced the machine’s frame using thicker materials (5x5cm) to boost stability and prolong its lifespan.

Enhanced performance and reliability

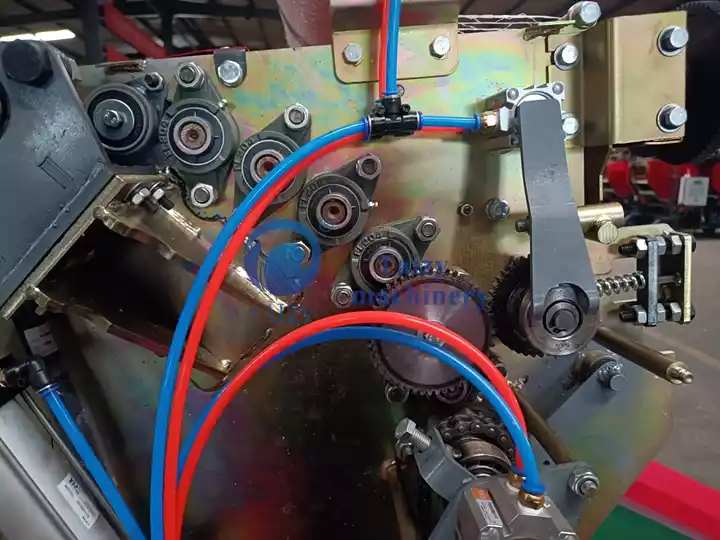

- Upgraded bearings to larger 204 bearings with thicker shafts for smoother operation and reduced failure rates.

- Used pickled cold steel plates for better corrosion resistance and lower maintenance needs.

Advanced conveyor and net binding system

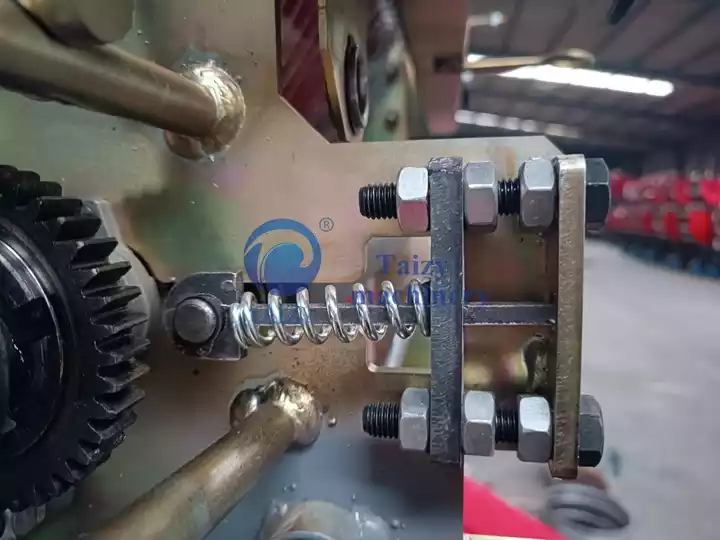

- Implemented a chain-controlled conveyor belt featuring a cylinder separator for automatic material feeding and halting.

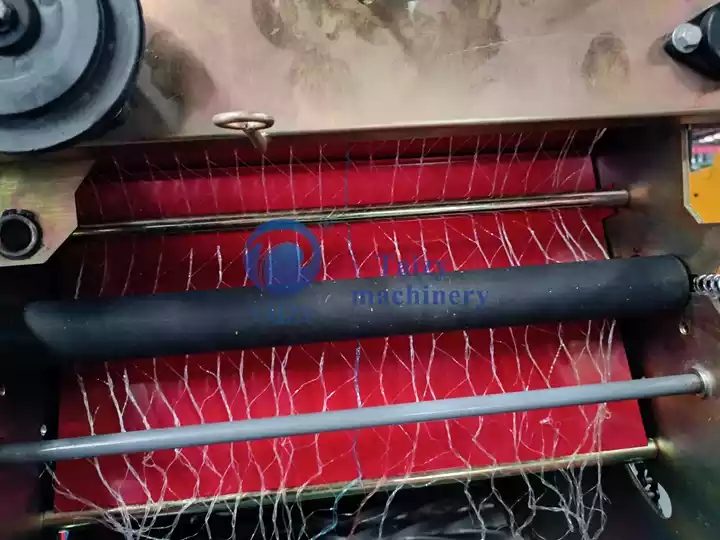

- Enhanced net binding by using thicker baling rollers, a higher net frame, and independent clutch control for improved operation.

Structural reinforcement

Added additional frame support beneath the wrapping machine to improve structural integrity and stability during heavy use.

If you have any additional requirements, we can also help you customize your corn silage baler machine. Please feel free to contact us.

Work video showcase

Silage baler wrapper technical specifications

| Model | TS-55-52 |

| Power | 5.5+1.1kw, 3 phase |

| Bale size | Φ550*520mm |

| Diesel engine | 15 hp |

| Baling speed | 40-50 piece/h, 4-5t/h |

| Size | 2135*1350*1300mm |

| Machine weight | 850kg |

| Bale weight | 65-100kg/bale |

| Bale density | 450-500kg/m³ |

| Rope consumption | 2.5kg/t |

| Wrapping machine power | 1.1-3kw, 3 phase |

| Film wrapping speed | 13s for 2-layer film,19s for 3-layer film |

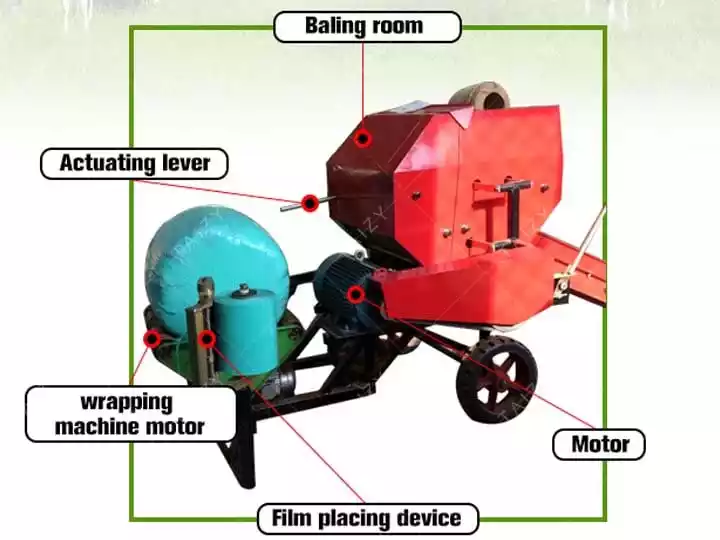

Components of round silage packing machine

The corn silage baler machine mainly includes a conveyor belt, baling chamber, wrapping system, and motor/diesel engine. The overall structure is simple and easy to understand and operate. The silage after baling is dense and easy to store and transport.

Workflow of the silage round baler

Firstly, put the silage on the conveyor belt of the corn silage baler machine. The conveyor belt will send the silage into the baling chamber. After the amount of silage reaches a certain amount, the light above the baling chamber will light up and we should stop feeding at this time.

Then the silage goes into the baling chamber. The baling chamber will roll the silage into round bales. At the same time, the bale will be baled with straw rope or net.

After baling, the silage enters the wrapping system, where the silage is wrapped.

Why is it necessary to bale the silage?

- The wrapped straw crop is suitable for long-term storage. The grass is not easy to deteriorate, and easy to transport. And is the choice of silage preparation for cattle, sheep, and livestock.

- Baling and high density. Suitable for extrusion baling of corn straw, wheat straw, rice straw, and pasture grass. It can greatly reduce the storage area and facilitate breeding.

- The corn silage baler machine can take up for the shortage and low quality of forage sources in the livestock industry. And reduce the cost of feeding, and improve the production and quality of meat or milk. So the forage industry has embarked on commercialization.

Welcome to other models of silage bale wrapping machines by clicking: Silage Wrapping Machine Hay Baler For Sale and New Belt-type Automatic Silage Baling And Wrapping Machine.

Whether you are a family farm or a large-scale agricultural production, our silage machines can help you to improve production efficiency and ensure feed quality. We sincerely welcome you to contact us anytime for more product details and professional advice.