秸秆切割回收机丨青贮收获机

| 姓名 | 谷壳收割机 |

| 引擎 | ≥60HP拖拉机 |

| 方面 | 1.6*1.2*2.8m |

| 重量 | 800公斤 |

| 收获宽度 | 1.3m |

| 模型 | GH-400 |

| 回收率 | ≥80% |

| 投掷距离 | 3-5m |

| 抛掷高度 | ≥2m |

| 碎秸秆长度 | 小于80毫米 |

| 旋转刀片 | 32 |

| 刀轴转速 | 2160转/分 |

| 工作速度 | 2-4公里/小时 |

| 容量 | 0.25-0.48h㎡/小时 |

您现在可以向我们的项目经理询问技术细节

秸秆切割回收机是一种多功能农业设备,集收割、粉碎和回收于一体,适用于各种作物秸秆和青贮的田间加工。它可以帮助农民将“废弃物”转化为饲料加工、生物质发电和有机肥料生产的资源。

支持操作的设备和拖拉机是一种多功能机器,可以实现现场粉碎秸秆并直接回收或返回田地。其粉碎颗粒度≤ 5cm,并且实现玉米、小麦、稻米等作物秸秆的回收率超过80%。

这款秸秆切割回收机配备了不同的收割宽度,如1.3米、1.35米、1.5米、1.65米、1.7米、1.8米和2米,适用于不同大小的农田,并且能够实现超高效的处理能力,达到0.25-0.48h㎡/h。

使用青贮收割机的范围

适用对象(可处理的作物类型)

- 玉米秸秆、棉花秸秆、香蕉秸秆、高粱秸秆、小麦秸秆、谷物秸秆及其他作物秸秆。

- 田间各种湿混和干混青贮作物。

- 各种果园收获后的残余秸秆和生物质秸秆。

场景和应用

- 用于青贮或秸秆颗粒饲料加工的农场和饲料厂。

- 炭厂、秸秆煤厂等,用于生产秸秆炭、秸秆煤和生物质燃料。

- 被食用菌种植者用于制作栽培基质。

- 可作为生物质发电的原料,实现能源回收。

青贮收割机是如何工作的?

当拖拉机在田间向前移动时,机器被驱动以同步操作,前端切割台将收获的秸秆送入粉碎装置进行粉碎。

随后,粉碎的稻草通过输送系统收集到回收箱中,或直接返回田地,实现了收割、粉碎和回收的集成高效运作。

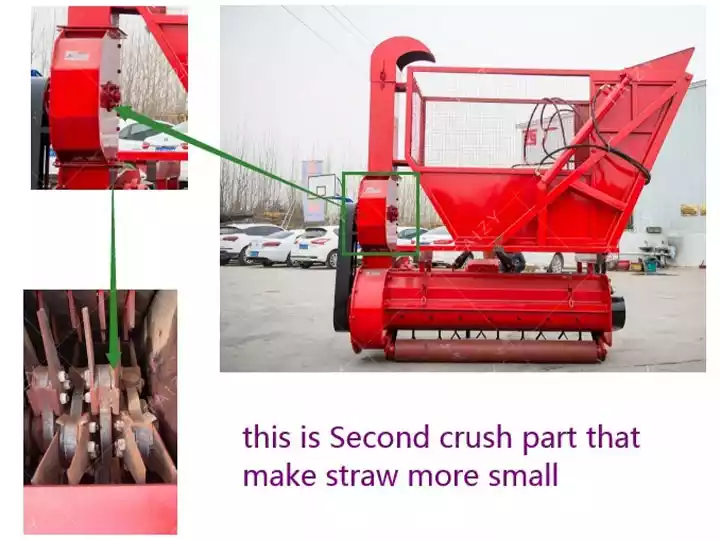

秸秆切割回收机的结构

秸秆切割回收机结构简单,操作方便。该机主要包括破碎室、液压自动卸料装置、60马力拖拉机、破碎秸秆容器、PTO驱动、液压装置等。

玉米青贮收割机参数

| 姓名 | 谷壳收割机 |

| 引擎 | ≥60HP拖拉机 |

| 方面 | 1.6*1.2*2.8m |

| 重量 | 800公斤 |

| 收获宽度 | 1.3m |

| 模型 | GH-400 |

| 回收率 | ≥80% |

| 投掷距离 | 3-5m |

| 抛掷高度 | ≥2m |

| 碎秸秆长度 | 小于80毫米 |

| 旋转刀片 | 32 |

| 刀轴转速 | 2160转/分 |

| 工作速度 | 2-4公里/小时 |

| 容量 | 0.25-0.48hm2/小时 |

拖拉式饲料收割机的优点

- 多功能集成:集切割、揉捏、粉碎和收获于一体,以满足不同的操作需求。

- 高效低耗:操作过程简化为一个程序,具有高操作效率和显著的节能效果。

- 综合成本低:能耗低,产出高,总体成本低,经济效益强。

- 广泛适用:可以适应多种干湿稻草作物,适合多种土地环境,具有很强的适应性。

- 推广绿色农业:帮助生物质能源的综合利用,是发展环保农业的理想设备。

成功案例

一位来自马来西亚的客户从我们这里购买了一台1.3米的秸秆切割回收机。他在当地喂养牛羊。为了获得足够的饲料,这位客户需要一台秸秆粉碎机来处理玉米秸秆。

我们将机器的图片、参数、视频发送给客户。客户考虑后,决定购买一台。客户收到秸秆切割回收机后,使用了一段时间。他表示机器性能非常好,很满意,期待与我们的下次合作。

除了秸秆切碎回收机,我们还有其他类型的青贮及其他加工设备,例如青贮打包裹包机和液压打包机。您可以浏览我们的网站自行选择合适的机器。欢迎随时联系我们!

常问问题

其功能是什么 秸秆切割回收机?

秸秆破碎回收功能。

可以只买粉碎部分吗?

是的,可以单独粉碎吸管(价格也便宜一些)。建议您使用料斗车跟随撕碎机。

你能处理干稻草吗?

是的,但是绿色稻草对于动物来说是最好的保鲜和储存。

机器需要多少马力?

80马力拖拉机,不同的收获宽度配合不同的拖拉机马力大小,以确认客户拖拉机马力大小。

粉碎后的茬高度是多少?

8-15厘米。

粉碎后的秸秆细度是多少?

是3-5cm。