Mashine ya kukatia mashina ya kuchakata mabua丨 Mashine ya kuvunia silage

| Jina | Kivuna makapi |

| Injini | ≥60HP trekta |

| Dimension | 1.6*1.2*2.8m |

| Uzito | 800kg |

| Upana wa kuvuna | 1.3m |

| Mfano | GH-400 |

| Kiwango cha kuchakata tena | ≥80% |

| Umbali wa kuruka | 3-5m |

| Urefu wa kuruka | ≥2m |

| Urefu wa majani yaliyoangamizwa | Chini ya 80 mm |

| Kisu kinachozunguka | 32 |

| Kasi ya shimoni ya kukata | 2160r/dak |

| Kasi ya kufanya kazi | 2-4km/saa |

| Uwezo | 0.25-0.48h㎡/saa |

Sasa unaweza kuwauliza wasimamizi wetu wa mradi kwa maelezo ya kiufundi

Mashine ya kukata shina ni vifaa vya kilimo vyenye matumizi mengi vinavyounganisha uvunaji, kusaga na kuchakata tena, ambavyo vinafaa kwa usindikaji wa shamba wa majani mbalimbali na silage. Inaweza kuwasaidia wakulima kubadilisha "vifaa vya taka" kuwa rasilimali za usindikaji wa chakula, uzalishaji wa nguvu za biomass na uzalishaji wa mbolea ya kikaboni.

Vifaa na trekta vinavyosaidia operesheni, mashine ya matumizi mengi, inaweza kufikia kukandamiza majani kwenye tovuti na kurejeleza moja kwa moja au kurudisha shambani. Ukubwa wa kukandamiza ni ≤ 5cm, na kufikia kiwango cha urejeleaji zaidi ya 80% kwa majani ya mahindi, ngano, mchele na mazao mengine.

Denna maskin för återvinning av stjälkskärning är utrustad med olika skördebredder som 1,3 m, 1,35 m, 1,5 m, 1,65 m, 1,7 m, 1,8 m och 2 m, som är lämpliga för olika storlekar av åkermark, och den kan uppnå en ultraeffektiv bearbetningskapacitet på 0,25-0,48 h㎡/h.

Användning av ensilage skördemaskin

Objekt som gäller (typer av grödor som kan behandlas)

- Majsstjälkar, bomullsstjälkar, bananstjälkar, sorghumstjälkar, vetestrå, kornstjälkar och andra grödstjälkar.

- Alla typer av våta och torra blandade ensilagegrödor på fältet.

- Alla typer av fruktträdgårdsrester och biomassa stjälkar efter skörd.

Scenarier och tillämpningar

- Gårdar och foderfabriker för ensilage eller stråpelletsfoderbearbetning.

- Kolgruvor, stråkolfabriker, etc. används för att producera stråkol, stråkol och biomassa bränsle.

- Används av odlare av ätliga svampar för att göra odlingssubstrat.

- Kan användas som råmaterial för biomassa kraftgenerering, vilket realiserar energirecirkulering.

Hur fungerar ensilage skördemaskinen?

När traktorn rör sig framåt på fältet, drivs maskinen för att synkronisera operationen, och den främre skärbordet skickar det skördade halmen till krossningsanordningen för malning.

Därefter samlas den krossade halmen i återvinningslådan genom transportsystemet, eller återförs direkt till fältet, vilket möjliggör en integrerad och effektiv drift av skörd, krossning och återvinning.

Struktur av stjälkskärande återvinningsmaskin

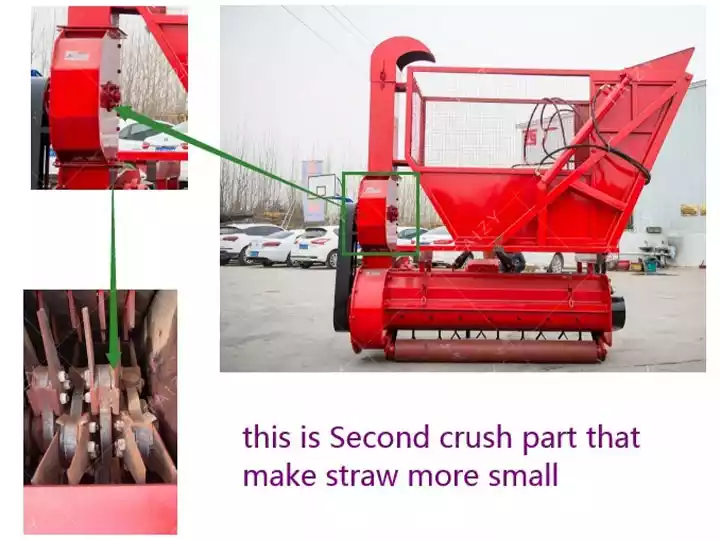

Muundo wa mashine ya kuchakata mabua ni rahisi na rahisi kufanya kazi. Mashine hasa inajumuisha chumba cha kusagwa, kifaa cha upakuaji wa majimaji kiotomatiki, trekta ya 60HP, chombo cha majani kilichokandamizwa, PTO inayoendeshwa, kifaa cha majimaji, nk.

Parametrar för majsensilage skördare

| Jina | Kivuna makapi |

| Injini | ≥60HP trekta |

| Dimension | 1.6*1.2*2.8m |

| Uzito | 800kg |

| Upana wa kuvuna | 1.3m |

| Mfano | GH-400 |

| Kiwango cha kuchakata tena | ≥80% |

| Umbali wa kuruka | 3-5m |

| Urefu wa kuruka | ≥2m |

| Urefu wa majani yaliyoangamizwa | Chini ya 80 mm |

| Kisu kinachozunguka | 32 |

| Kasi ya shimoni ya kukata | 2160r/dak |

| Kasi ya kufanya kazi | 2-4km/saa |

| Uwezo | 0.25-0.48hm2/saa |

Fördelar med släpvagnsgräsklippare

- Multifunktionell integration: integrering av skärning, knådning, krossning och skörd för att möta olika driftsbehov.

- Hög effektivitet och låg förbrukning: driftsprocessen har förenklats till en procedur, med hög drifteffektivitet och anmärkningsvärd energibesparande effekt.

- Låg total kostnad: låg energiförbrukning, hög produktion, lägre totalkostnad och stark ekonomi.

- Inatumika sana: inaweza kubadilishwa kwa aina mbalimbali za mazao ya majani kavu na mvua, inafaa kwa mazingira mbalimbali ya ardhi, na ina matumizi makubwa.

- Promovet jordbruket grønt: hjelp den omfattende utnyttelsen av biomasseenergi, er det ideelle utstyret for utviklingen av miljøvennlig jordbruk.

Kesi zilizofanikiwa

Mteja kutoka Malaysia alinunua mashine ya kusaga makasha ya 1.3m kutoka kwetu. Anawapa ng'ombe na kondoo chakula katika eneo lake. Ili kupata chakula cha kutosha, mteja alihitaji mashine ya kusaga majani ili kushughulikia makasha ya mahindi.

Tulituma picha, vigezo na video za mashine kwa mteja. Baada ya kuzingatia, mteja aliamua kununua moja. Baada ya mteja kupokea mashine ya kuchakata mabua, aliitumia kwa muda. Alisema mashine hiyo ilifanya kazi vizuri sana na aliridhika nayo na anatarajia ushirikiano mwingine na sisi.

Mbali na mashine za kusaga na kuchakata mabua, pia tuna aina zingine za malisho na vifaa vingine vya usindikaji, kama vile mashine za kufungia malisho na mashine za kufungia za majimaji. Unaweza kuvinjari tovuti yetu kuchagua mashine inayofaa mwenyewe. Karibu kuwasiliana nasi wakati wowote!

Maswali Yanayoulizwa Mara kwa Mara

Je, ni nini kazi ya mashine ya kuchakata mabua?

Kazi ya kusagwa kwa majani na kuchakata tena.

Je, ninaweza kununua sehemu ya kusagwa tu?

Ndiyo, unaweza kuponda majani tofauti (bei pia ni nafuu). Inapendekezwa kwamba utumie lori ya hopper kufuata shredder.

Je, unaweza kushughulikia nyasi kavu?

Ndio, lakini majani ya kijani kibichi ndio bora zaidi kwa ubichi na uhifadhi wa wanyama.

Je, mashine inahitaji nguvu ya farasi kiasi gani?

Trekta ya hp 80, upana tofauti wa kuvuna na ukubwa tofauti wa nguvu za farasi wa trekta, ili kuthibitisha ukubwa wa uwezo wa farasi wa trekta ya mteja.

Je, urefu wa makapi baada ya kusagwa ni nini?

8-15cm.

Uzuri wa majani yaliyosagwa ni nini?

Ni 3-5 cm.