Mashine Mpya ya Kufunga na Kufunga Silaji aina ya Mkanda

| Mfano | 9YDB-60 |

| Ukubwa wa bale (mm) | Φ600*520 |

| Uzito wa bale (kg) | 90-140 |

| Uwezo | Vifurushi 50-75 / h |

| Kasi iliyokadiriwa(r/min) | 350 |

| Nguvu inayounga mkono (kW) | 7.5kW-6 |

| Ukubwa wa mashine(mm) | 3500*1450*1550 |

| Filamu inayolingana ya lishe (L*W*H) | 1800m*250mm*25mm |

Sasa unaweza kuwauliza wasimamizi wetu wa mradi kwa maelezo ya kiufundi

Tumekuwa tukijikita katika uzalishaji na usafirishaji wa mashine za kufunga na kufunika silage kwa miaka mingi na tumepata uzoefu mkubwa katika tasnia. Sasa tunajivunia kuzindua kizazi kipya cha mashine ya kufunga silage ya aina 60 (9YDB-60).

Vifaa vinatumia muundo wa chumba cha kubana na muundo wa mkanda wa herringbone, na vina kazi nyingi za akili kama vile kubana kiotomatiki kabisa, kuvuta filamu, kufungua na kufunga hatch, na kutoa mfuko kwa nyuma.

Inabala 50-75 bales kwa saa, kila bale ina uzito kati ya 90-140 kg, na ukubwa wa bale ni Φ600×520mm. Wiani wa bale moja unazidi 800kg/m³, na uwezo wa usindikaji wa kila siku unaweza kufikia tani 48. Ni vifaa bora kwa ajili ya kubalisha na kufunga katika ranchi na sekta za ufugaji.

Vikundi vinavyotumika vya mashine

- Farms and farms: såsom mejerigårdar, nötkreatursgårdar, fårgårdar, etc. Det är lämpligt för att pressa och bevara stora mängder ensilage.

- Cooperativ jordbruk och familjejordbruk: lämpliga för små och medelstora kooperativa enheter som kombinerar odling och uppfödning, förbättrar effektiviteten i skörd och lagring samt minskar arbetskostnaderna.

- Kampuni kubwa za kilimo: fanya operesheni ya kubalisha kiotomatiki kwa ufanisi wakati wa msimu wa mavuno ya silage, ambayo ni rahisi kwa usafirishaji na uhifadhi wa muda mrefu.

- Tjänsteleverantör för uthyrning av jordbruksmaskiner: lämplig för att tillhandahålla pressningstjänst som effektiv driftsutrustning för att möta olika kundbehov.

Matumizi ya mashine za kufungia malisho

- Bevarande av foder: används främst för att pressa och filma olika typer av foder som gräs, halm, ensilage, etc. för långtidslagring. Det filmade fodret isoleras från luften för att förhindra jäsning och mögel, vilket därmed bevarar det näringsmässiga innehållet i fodret.

- Behandling ya taka: inaweza kuchakata taka za kilimo kama vile majani ya mazao, maganda, shina za mahindi, nk, na kuyapakia na kuyahifadhi kwa matumizi ya chakula au madhumuni mengine ili kupunguza uchafuzi wa mazingira.

- Produktion av ensilage: genom filmbeläggning och jäsning görs färskt fodergräs eller grödorester till högkvalitativt ensilage, som är lämpligt för att utfodra boskap som nötkreatur och får för att förbättra deras näringsstruktur.

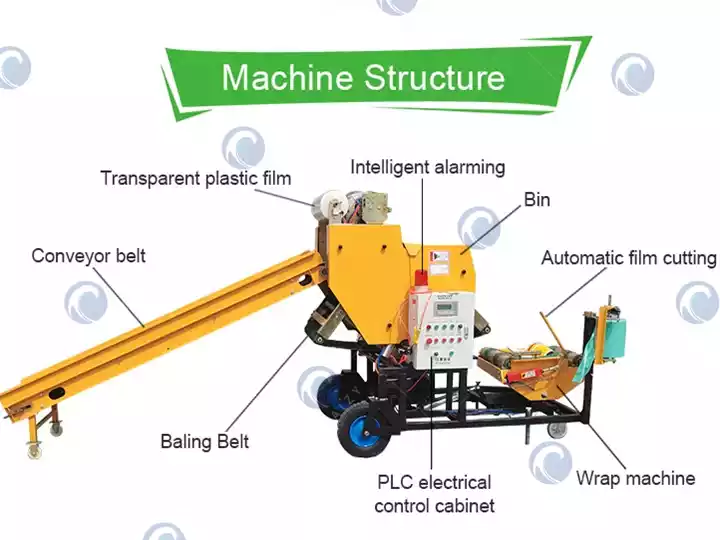

9YDB-60 Muundo wa mashine ya kufungia silaji na ya kufunga

Mashine hii hasa ina sehemu mbili, ikiwa ni pamoja na baling bin na sehemu ya kufunika filamu.

Mashine mpya ya 9YDB-60 ya kuwekea silaji na kuifunga inatofautiana na miundo ya awali ya TZ-55-52 na 70 kwa kuwa miundo miwili ya kwanza iliweza kutumia kamba za majani na nyavu kwa ajili ya chakula cha kuwekea, wakati 9YDB-60 mpya inaweza kutumia tu. filamu ya uwazi ya plastiki kwa baling.

Onyesho la maelezo ya baler ya Hay

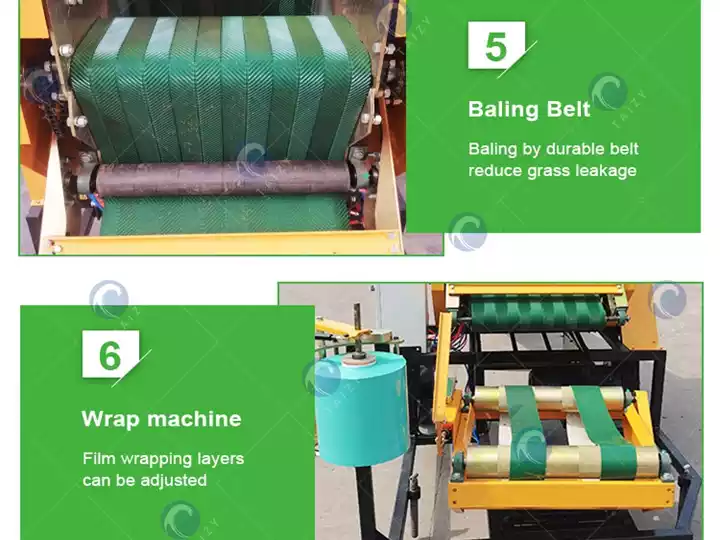

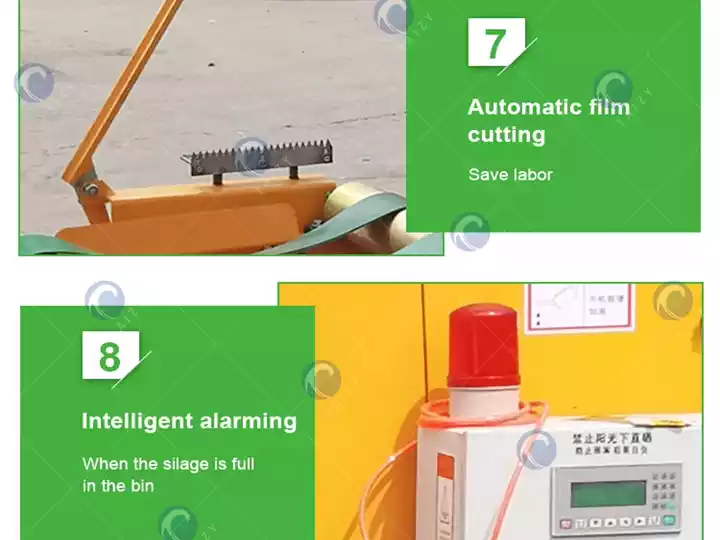

Baada ya kuelewa muundo wa jumla wa mashine ya kufunga na kufunga silage, hebu tuingie katika maelezo ya baadhi ya vipengele muhimu. Vipengele hivi vina jukumu muhimu katika uendeshaji bora na utendaji wa kuaminika wa mashine.

Följande kommer att använda några detaljerade visningsdiagram för att hjälpa dig att mer intuitivt förstå de strukturella detaljerna och arbetsprinciperna för denna maskin.

Kanuni ya kazi ya mashine ya silage baler

Nyenzo ghafi za mashine ya kukandamiza na kufunga silaji kwa kawaida huchakatwa na kitengeneza nyasi. Kulingana na mahitaji yako ya ubora wa silaji iliyokamilishwa, tunatoa aina tofauti za mashine za kukata nyasi. Unaweza kujifunza zaidi kuzihusu kwa kubofya https://balerwrapper.com/products/chaff-cutter/. Nyasi iliyochakatwa hufungwa na kufungwa kupitia mchakato ufuatao.

Baling ya kulisha silage

Lishe hulishwa haraka na sawasawa ndani ya pipa la baling kupitia ukanda wa kulisha. Vifaa vya kukandamiza kama vile mshipa wa sill katika pipa hubana lishe kwenye marobota ya silinda ya takriban kilo 120, ambayo hufungwa kwa filamu ya plastiki.

Sehemu ya kufunga

Mabao yaliyofungwa yamefungwa na kifaa cha kukunja filamu, ambacho huvuta filamu ya plastiki kiotomatiki na kuifunga sawasawa kwenye uso wa bale ili kuhakikisha kwamba bale imefungwa kabisa kwenye filamu ili kutenga hewa na kuzuia kuchacha na ukungu.

Vigezo vya kiufundi vya malisho ya kiotomatiki

| Mfano | Mfano wa Ukanda wa Juu 9YDB-60 | Ukubwa wa bale (mm) | Φ600*520 |

| Uzito wa bale (kg) | 90-140 | Nguvu inayounga mkono (kW) | 7.5kW-6 |

| Kasi iliyokadiriwa(r/min) | 350 | Injini ya compressor ya hewa | 1.5kw |

| Njia ya kufunga bale | Otomatiki | Kiasi cha pampu ya hewa (lita) | 30 |

| Idadi ya rollers za alumini (pcs) | Roli 8 kwa pipa linalohamishika Fixed bin 9 rollers | Mashine ya kufunga filamu | 0.75kw |

| Tabaka za kufunga filamu | Marekebisho ya kukabiliana | Inre väggtjocklek (mm) | 6 |

| Nyenzo za kuunganisha | Filamu ya plastiki ya lishe | Njia ya kuvuta filamu | Otomatiki |

| Plastfilmspänning | Marekebisho ya kukabiliana | Kipunguza kasi cha mashine ya kufunga filamu | Gia ya minyoo |

| Marekebisho ya wiani | Marekebisho ya sasa ya Superman ndogo | Uendeshaji wa sanduku la usambazaji wa nguvu | Operesheni ya Mwongozo/otomatiki |

| Alumini roller kuzaa | FC205(skurubu 4 za kurekebisha) | Bonyeza roller | 8 filimbi |

| Matningskonveyorrem (mm) | L 2500×517 | Rullaxeltjocklek (mm) | 30 |

| Fast bin rem (mm) (herringbone rem) | 2300×517 | Kufagia hewa bunduki | ndio |

| Rörlig bin rem (mm) (herringbone rem) | 2470×517 | Mbinu ya ufungaji wa kuzaa | Mashine ni ya nje kabisa. |

| Remtjocklek (mm) | 5 | ||

| Nyenzo za roller za alumini | Utoaji wa aloi ya alumini | Ukubwa wa mashine(mm) | 3500*1450*1550 |

| Mfano wa mnyororo | 12Mnyororo wa viwanda | Sura ya kuchana filamu | Mtindo mpya wa chemchemi mbili |

| Uwezo | Vifurushi 50-75 / h | Mashine nzima | Kunyunyizia plastiki |

| Kufungua na kufunga pipa | Otomatiki | Kugeuza na kurudisha kifungu | Otomatiki |

| Kulinganisha filamu ya ndani (maalum) | 2000m urefu 525mm upana 15kg | Kulingana na filamu ya lishe (L*W*H) | 1800m*250mm*25mm |

Kifaa cha kuunga mkono baler ya sileji

Unapotumia hii silaji mashine ya kukandamiza na kufunga, tunapendekeza kutumia kifaa cha kulishia kiotomatiki ili kuhakikisha kuwa malisho yanaweza kulishwa bila kukoma na kwa usawa. Kwa kuongezea, tunatoa gari bila malipo ili kuwezesha usafirishaji wa mafungu yaliyokamilishwa.

Ikiwa unataka kujua aina zingine za mashine za kukandamiza na kufunga silaji, tafadhali bonyeza Mashine ya Kiotomatiki ya Kukandamiza Silaji ya Mahindi kwa Uhifadhi wa Malisho na Mashine ya Kufunga Silaji Mashine ya Kukandamiza Nyasi kwa Uuzaji.

Ikiwa una maswali au mahitaji yoyote kuhusu bidhaa zetu, tafadhali jisikie huru kuwasiliana nasi. Pia tunakualika kwa dhati kutembelea kiwanda chetu ili kujifunza kuhusu mchakato wetu wa uzalishaji na uendeshaji wa vifaa ana kwa ana. Kuangalia mbele kwa kushirikiana na wewe!