Mesin daur ulang pemotongan tangkai丨mesin pemanen silase

| Nama | Pemanen sekam |

| Mesin | Traktor ≥60HP |

| Dimensi | 1,6*1,2*2,8m |

| Berat | 800kg |

| Lebar panen | 1,3m |

| Model | GH-400 |

| Tingkat daur ulang | ≥80% |

| Jarak lempar | 3-5m |

| Ketinggian lemparan | ≥2m |

| Panjang jerami yang dihancurkan | Kurang dari 80mm |

| Pisau berputar | 32 |

| Kecepatan poros pemotong | 2160r/menit |

| Kecepatan kerja | 2-4km/jam |

| Kapasitas | 0,25-0,48 jam㎡/jam |

Anda sekarang dapat bertanya kepada manajer proyek kami untuk rincian teknis

Mesin daur ulang pemotongan batang adalah peralatan pertanian multifungsi yang mengintegrasikan panen, penghancuran, dan daur ulang, yang cocok untuk pemrosesan lapangan berbagai jerami tanaman dan silase. Ini dapat membantu petani mengubah "bahan limbah" menjadi sumber daya untuk pemrosesan pakan, pembangkit listrik biomassa, dan produksi pupuk organik.

Peralatan dan traktor yang mendukung operasi, sebuah mesin serbaguna, dapat melakukan penghancuran jerami di lokasi dan mendaur ulang atau mengembalikannya langsung ke ladang. Ukuran penghancurannya ≤ 5cm, dan dapat mencapai tingkat pemulihan jerami dari jagung, gandum, padi, dan tanaman lainnya lebih dari 80%.

Mesin daur ulang pemotongan batang ini dilengkapi dengan berbagai lebar panen seperti 1,3m, 1,35m, 1,5m, 1,65m, 1,7m, 1,8m, dan 2m, yang cocok untuk berbagai ukuran lahan pertanian, dan dapat mewujudkan kapasitas pemrosesan ultra-efisien sebesar 0,25-0,48h㎡/h.

Menggunakan ruang mesin pemanen silase

Objek yang berlaku (jenis tanaman yang dapat diolah)

- Batang jagung, batang kapas, batang pisang, batang sorgum, jerami gandum, batang biji-bijian dan batang tanaman lainnya.

- Segala jenis campuran silase basah dan kering di lapangan.

- Segala jenis jerami sisa kebun dan batang biomassa setelah panen.

Skenario dan aplikasi

- Peternakan dan pabrik pakan untuk pengolahan silase atau pakan pelet jerami.

- Pabrik arang, pabrik arang jerami, dll. digunakan untuk memproduksi arang jerami, arang jerami, dan bahan bakar biomassa.

- Digunakan oleh petani jamur edible untuk membuat substrat budidaya.

- Dapat digunakan sebagai bahan baku untuk pembangkit listrik biomassa, mewujudkan daur ulang energi.

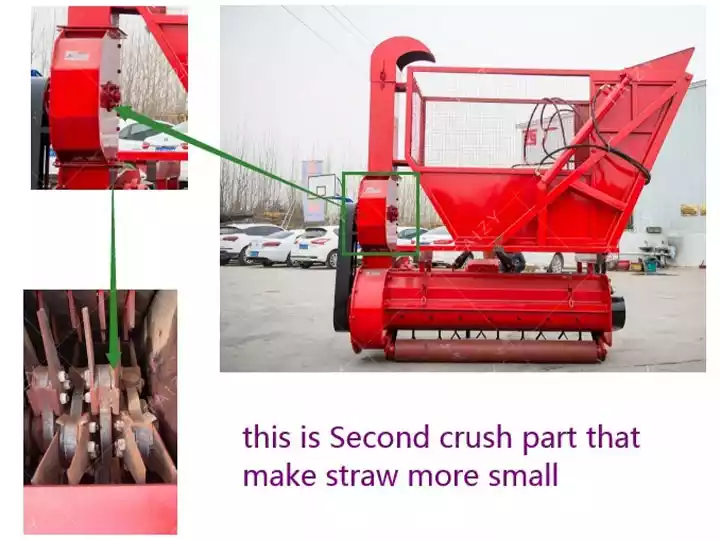

Bagaimana cara kerja mesin pemanen silase?

Ketika traktor bergerak maju di ladang, mesin dioperasikan untuk menyinkronkan operasi, dan meja pemotong bagian depan mengirimkan jerami yang dipanen ke perangkat penghancur untuk dihancurkan.

Selanjutnya, jerami yang dihancurkan dikumpulkan ke dalam kotak daur ulang melalui sistem pengangkutan, atau dikembalikan langsung ke ladang, mewujudkan operasi yang terintegrasi dan efisien dari panen, penghancuran, dan daur ulang.

Struktur mesin daur ulang pemotong batang

Struktur mesin daur ulang pemotongan batang sederhana dan mudah dioperasikan. Mesin ini terutama mencakup ruang penghancur, perangkat pembongkaran otomatis hidrolik, traktor 60HP, wadah jerami yang dihancurkan, penggerak PTO, perangkat hidrolik, dll.

Parameter pemanen silase jagung

| Nama | Pemanen sekam |

| Mesin | Traktor ≥60HP |

| Dimensi | 1,6*1,2*2,8m |

| Berat | 800kg |

| Lebar panen | 1,3m |

| Model | GH-400 |

| Tingkat daur ulang | ≥80% |

| Jarak lempar | 3-5m |

| Ketinggian lemparan | ≥2m |

| Panjang jerami yang dihancurkan | Kurang dari 80mm |

| Pisau berputar | 32 |

| Kecepatan poros pemotong | 2160r/menit |

| Kecepatan kerja | 2-4km/jam |

| Kapasitas | 0,25-0,48hm2/jam |

Keuntungan dari pemanen pakan yang ditarik

- Integrasi multi-fungsi: mengintegrasikan pemotongan, pengulungan, penghancuran, dan panen untuk memenuhi berbagai kebutuhan operasional.

- Efisiensi tinggi dan konsumsi rendah: proses operasi disederhanakan menjadi satu prosedur, dengan efisiensi operasi yang tinggi dan efek penghematan energi yang luar biasa.

- Biaya komprehensif rendah: konsumsi energi rendah, output tinggi, biaya keseluruhan lebih rendah dan ekonomi yang kuat.

- Dapat diterapkan secara luas: dapat disesuaikan dengan berbagai jenis tanaman jerami kering dan basah, cocok untuk berbagai lingkungan lahan, dan memiliki daya aplikatif yang kuat.

- Promosikan pertanian hijau: bantu pemanfaatan komprehensif energi biomassa, adalah peralatan ideal untuk pengembangan pertanian ramah lingkungan.

Kasus yang berhasil

Seorang pelanggan dari Malaysia membeli mesin daur ulang pemotong batang 1,3m dari kami. Dia memberi makan sapi dan domba di daerahnya. Untuk mendapatkan pakan yang cukup, pelanggan tersebut membutuhkan penggiling jerami untuk memproses batang jagung.

Kami mengirimkan gambar, parameter, dan video mesin ke pelanggan. Setelah mempertimbangkan, pelanggan memutuskan untuk membelinya. Setelah pelanggan menerima mesin daur ulang pemotongan batang, dia menggunakannya sebentar. Dia mengatakan mesin tersebut bekerja dengan sangat baik dan dia puas dengannya serta menantikan kerja sama berikutnya dengan kami.

Selain mesin penghancur dan daur ulang jerami, kami juga memiliki berbagai jenis silase dan peralatan pengolahan lainnya, seperti mesin pembungkus pakan dan mesin baler hidrolik. Anda dapat menjelajahi situs web kami untuk memilih mesin yang tepat sendiri. Silakan hubungi kami kapan saja!

Pertanyaan Umum

Apa fungsi dari mesin daur ulang pemotongan batang?

Fungsi penghancuran dan daur ulang jerami.

Bisakah saya membeli bagian penghancurnya saja?

Bisa, sedotannya bisa dihancurkan secara terpisah (harganya juga lebih murah). Disarankan agar Anda menggunakan truk hopper untuk mengikuti mesin penghancur.

Bisakah Anda menangani sedotan kering?

Ya, tapi jerami hijau adalah yang terbaik untuk kesegaran dan penyimpanan hewan.

Berapa tenaga kuda yang dibutuhkan mesin tersebut?

Traktor 80 hp, lebar pemanenan berbeda dengan ukuran tenaga kuda traktor berbeda, untuk memastikan ukuran tenaga kuda traktor pelanggan.

Berapa tinggi tunggul setelah dihancurkan?

8-15cm.

Berapa kehalusan jerami yang dihancurkan?

Ini adalah 3-5cm.