Machine de découpe d'herbe d'alimentation animale de coupeur de paille d'ensilage

| Modèle | 9Z-1.2 |

| Pouvoir de soutien | Moteur monophasé de 3 kW |

| Vitesse du moteur | 2800 tr/min |

| Poids de la machine | 80KG |

| Dimensions | 880*1010*1750mm |

| Efficacité de production | 1200 KG/H |

| Nombre de lames | 6 |

| Méthode d'alimentation | Alimentation manuelle |

| Effet de décharge | 7-35mm |

| Type de structure | disque |

Vous pouvez désormais demander des détails techniques à nos chefs de projets

Notre coupeuse de fourrage multifonctionnelle est conçue pour les fermes modernes, capable de répondre à la demande d'alimentation fine de différents animaux d'élevage tels que les vaches, les moutons, les porcs, etc., dans des fermes de différentes tailles.

Des exploitations familiales aux bases d'élevage à grande échelle, nous proposons une gamme complète de modèles, équipés de systèmes d'alimentation électriques, à essence et diesel, avec un choix flexible de capacité de manutention quotidienne allant de quelques tonnes à des dizaines de tonnes.

Le coupeur de chaff de silage peut être associé à une machine de pressage et d'emballage de silage, à un tapis roulant et à d'autres équipements pour former une ligne de production automatique. Cela permet de réaliser une opération clé en main, du traitement des matières premières à l'emballage du produit fini, vous aidant à améliorer le traitement des aliments et à réduire les coûts de main-d'œuvre.

Gamme d'applications de la machine de coupe-balles pour aliments pour animaux

Nos hacheurs de fourrage peuvent traiter efficacement tous les types de tiges de culture et de matières premières fourragères, y compris les tiges de maïs vert (sec), la paille de riz-blé, les semis de soja, l'herbe éléphant, etc.

L'alimentation de haute qualité traitée est particulièrement adaptée aux bovins, ovins, cerfs, chevaux et autres élevages de bétail, ce qui peut améliorer considérablement la palatabilité et la valeur nutritionnelle de l'alimentation.

En plus de l'élevage de bétail, l'équipement est également largement utilisé dans :

- Énergie biomasse : fourniture de matières premières en paille standardisées pour les centrales électriques.

- Industrie papetière : prétraitement de divers types de matières premières en fibres végétales.

- Raffinage de l'éthanol : matières premières végétales de haute qualité pour la préparation de biocarburant.

- Transformation de la médecine traditionnelle chinoise : découpe précise de matières végétales médicinales.

Type 1 : machine de coupe d'herbe 9Z-0.4

Conçu pour les exploitations familiales et les petites fermes, la machine à hacher l'ensilage 9Z-0.4 est compacte mais puissante !

Adoptant un ensemble de lames en alliage de haute précision comme système de coupe principal, grâce à la conception de lames ajustables, vous pouvez contrôler librement la longueur de coupe de l'herbe (1-5 cm au choix), parfaitement adapté aux besoins alimentaires de différents animaux.

Paramètres de la machine de coupe d'herbe

| Modèle | 9Z-0.4 |

| Pouvoir de soutien | Moteur électrique 3 kw |

| Vitesse du moteur | 2800 tr/min |

| Poids de la machine | 60KG (moteur non inclus) |

| Dimensions | 1050*490*790mm |

| Efficacité de production | 400-1000 KG/H |

| Nombre de lames | 4/6 |

| Méthode d'alimentation | alimentation automatique |

| Effet de décharge | 10-35mm |

| Type de structure | Type de tambour |

Performances de travail de la désileuse

Type 2 : 9Z-0,4 machine à couper l'herbe à bouche carrée

Le haut de cette machine à hacher l'herbe est spécialement équipé d'un port d'alimentation carré multifonctionnel, ce qui vous permet d'ajouter facilement une variété de matériaux auxiliaires nutritifs tels que des têtes de canne à sucre, des patates douces, des soja, etc. tout en hachant l'herbe, réalisant ainsi le ratio doré de la nutrition des aliments.

Informations détaillées sur le coupe-herbe

| Modèle | Coupe-paille 9Z-0.4 à bouche carrée |

| Pouvoir de soutien | Moteur électrique 3 kw |

| Vitesse du moteur | 2800 tr/min |

| Poids de la machine | 60KG |

| Dimensions | 1130*500*1190mm |

| Efficacité de production | 400-1000 KG/H |

| Nombre de lames | 4/6 |

| Méthode d'alimentation | alimentation automatique/manuelle |

| Effet de décharge | 10-35mm |

| Type multifonctionnel | Couper l'herbe et les légumes |

Structure du coupe-herbe

La structure du coupe-foin de type I et de type II est similaire. Ils contiennent tous deux une entrée de coupe, une chambre à guillotine, un réducteur, des roulettes mobiles et un moteur en cuivre pur. Le coupe-foin de type II a une ouverture d'alimentation carrée supplémentaire au-dessus de la chambre à guillotine. Ci-dessous se trouve le diagramme de structure de la machine à couper le foin 9Z-0.4 de type I.

Quelles sont les caractéristiques d’un broyeur d’herbe ?

- Conception robuste et durable : le support en fonte pleine et le corps en acier au manganèse garantissent la stabilité et la résistance à l'usure de l'équipement, prolongeant ainsi sa durée de vie.

- Système de coupe haute efficacité : trois ensembles de couteaux mobiles + conception de couteau fixe biseauté, structure d'alimentation tangentielle, réduction de la résistance de 30 %, amélioration de l'uniformité de coupe.

- Économie d'énergie silencieuse intelligente : la structure optimisée réduit le bruit, l'entraînement par engrenage réduit la consommation d'énergie de 20 %, adapté à une utilisation prolongée.

- Efficacité élevée flexible et polyvalente : alimentation à double rouleau avec espacement de couteau réglable (1-10 cm), traitement de 0,5 à 1 tonne par heure, efficacité 20 fois supérieure à celle du manuel.

Type 3 : Grand coupe-paille

- Notre gamme de coupeuses de fourrage à haute puissance comprend 8 modèles allant de 9Z-1.2 à 9Z-10A, chacun d'eux étant conçu avec une sortie à long cou pour garantir une livraison plus longue et plus fluide du foin.

- Les modèles 9Z-2.5A et 9Z-10A sont spécialement équipés d'un système d'alimentation automatique, qui permet une automatisation complète et améliore considérablement l'efficacité de production.

- En termes de sélection de puissance, toute la série prend en charge trois configurations : moteur électrique, moteur diesel et moteur à essence, et les modèles de plus de 1,8 tonne sont recommandés pour être propulsés par un moteur électrique ou un moteur diesel plus puissant afin d'assurer un fonctionnement stable sur une longue période.

- Le système de décharge par jet unique peut pulvériser puissamment l'herbe traitée à une distance de 8 à 15 mètres, la hauteur et l'angle de décharge peuvent être librement ajustés, ce qui facilite le raccordement au véhicule de transport ou au silo de stockage.

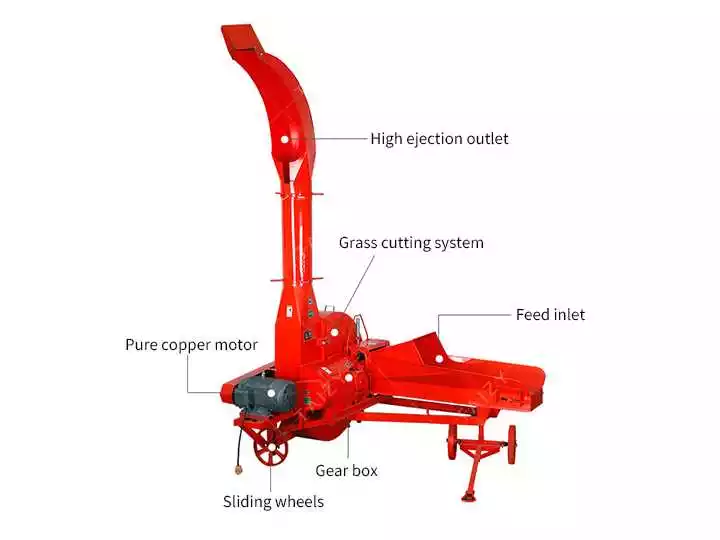

Structure d'une grande machine de découpe de paillettes de paille

La structure du grand broyeur de fourrage est similaire : tous deux contiennent une entrée de chargement, un réducteur, un dispositif de coupe, un haut tuyau, un moteur / moteur diesel, des roues mobiles, un cadre, etc.

Paramètres de la machine de découpe de paille 9Z-1.2

| Modèle | 9Z-1.2 |

| Pouvoir de soutien | Moteur monophasé de 3 kW |

| Vitesse du moteur | 2800 tr/min |

| Poids de la machine | 80KG |

| Dimensions | 880*1010*1750mm |

| Efficacité de production | 1200 KG/H |

| Nombre de lames | 6 |

| Méthode d'alimentation | Alimentation manuelle |

| Effet de décharge | 7-35mm |

| Type de structure | disque |

Avantages du grand broyeur de paille

- Structure en acier, petit volume, légèreté, facile à déplacer.

- Concevoir un dispositif d'assurance, pour éliminer les accidents de rongement de couteau, la machine est sûre et fiable.

- L'arbre d'entraînement du rouleau à herbe utilise un accouplement universel, une structure compacte, un fonctionnement flexible et un démontage et un assemblage faciles.

- La puissance de support est variée, moteur électrique, moteur diesel, le tracteur peut être adapté, surtout car le manque d'électricité dans la région est plus adapté.

- La lame de la machine est en acier de haute qualité, raffinée par une technologie spéciale et résistante à l'usure. L'utilisation de boulons à haute résistance, l'utilisation de matériaux sûrs et fiables.

- La coque du coupe-paille d'ensilage est constituée d'une plaque d'acier épaissie soudée en continu, l'ensemble du moule formant, beau et durable.

Principe de fonctionnement du grand coupe-paille

Que ce soit un coupe-foin à ensilage de grande ou de petite taille, le principe de fonctionnement est le même. Le moteur, le moteur diesel et le moteur à essence transmettent la puissance de la courroie à l'arbre principal. L'engrenage à l'autre extrémité de l'arbre principal transmet la puissance régulée en vitesse.

Lorsque le matériau entre entre les rouleaux de presse supérieurs et inférieurs par l'entrée. Ensuite, les couteaux tournants à grande vitesse effectuent rapidement l'opération de coupe de l'herbe. Enfin, l'herbe coupée est expulsée de la machine par la sortie.

Il peut être utilisé avec un équipement de film de conditionnement par la suite, veuillez cliquer pour plus de détails : Machine à ensiler le maïs automatique pour la préservation de l'alimentation.

Cas réussi

Un client des Philippines a acheté une hacheuse à silage 9Z-1.2 chez nous. Le client élève des bovins. Il y a quelque temps, il a décidé d'élargir l'échelle de son élevage. Il a donc également souhaité acheter un modèle plus grand de la guillotine pour traiter le fourrage.

Si vous avez des besoins en traitement d'ensilage, n'hésitez pas à nous contacter pour plus de détails sur l'équipement, une démonstration vidéo et un service personnalisé !