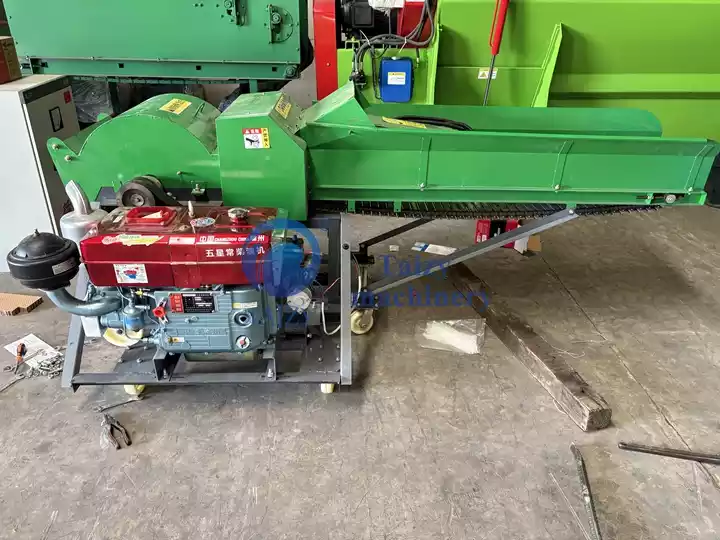

スイスに出荷された5セットのサイレージチョッパーマシン

良いニュース!私たちの工場は、5セットのサイレージチョッパーマシンを仕上げて出荷しました。顧客はスイス出身で、3,000頭の牛肉と乳牛の繁殖基地があります。主にサイレージ加工と高級乳製品と肉製品の供給に従事しています。

顧客の背景情報

顧客のローカルエリアには、バガス、キャッサバの茎、アルファルファ、その他の高繊維作物の茎が豊富です(ファイバー含有量> 35%、硬度インデックス8.2KN)。

ただし、原材料のサイズが大きく、粗くて硬いテクスチャーがあり、伝統的なギロチンストローチョッピング装置には、不均一なチョッピング、過剰なほこり、速い刃摩耗の問題があり、サイレージ発酵の効率が不十分です。

既存の機器とアップグレード要件

- 以前に購入したBaleラッピングマシンは、わらのベール(85%-90%に維持されている湿度)の密閉された保管を実現しますが、前処理リンクは手動のチョッピングに依存しているため、原材料の損失率が高くなります。スイスでは、夏には湿度が80%を超えています。

- 夏には、スイスの湿度は80%以上に達し、粗い繊維原料はカビを簡単にするため、24時間以内に混乱フィルムラッピングのプロセス全体を完了する必要があります。

- コスト最適化目標:機械化速度は95%に増加し、サイレージの生産コストを大幅に削減します。

サイレージチョッパーマシンソリューションとハイライト

- デュアル軸の微分ギロチン切断 +ハンマーブレード二次粉末、繊維の長さは5〜30mmで制御できます。

- タングステン - コバルト合金、硬度HRC62でコーティングされたブレードが装備されており、寿命は従来の機器の3倍長く。

- この機器は、30%-60%の水分含有量でストローの柔軟な処理をサポートし、高温動作による繊維炭化を回避します。

- 熱帯気候のために、この機械は雨季の高強度操作の需要を満たすために、腐食耐性ステンレス鋼の住宅と防水モーターを採用しています。

- このマシンは、顧客の既存の塩漬けおよびラッピングマシンとシームレスに統合されており、粉砕された原料は自動コンベアベルトを介してbal骨プロセスに直接移動し、中間損失を減らします。

サイレージチョッパーマシンにご興味のある方は、こちらをクリックしてください。サイレージチョップカッター動物飼料草刈機詳細はこちら。お見積もりについては、お気軽にお問い合わせください。